Abstract

This research paper provides an exhaustive and in-depth analysis of contemporary intelligent heating solutions, meticulously dissecting the operational principles, technical specifications, multifaceted advantages, inherent disadvantages, precise efficiency metrics, and critical safety considerations pertaining to both underfloor heating systems and various classifications of portable heaters. The investigation specifically focuses on underfloor heating technologies, encompassing both hydronic (water-based) and electric variants, alongside a comprehensive review of portable heating appliances, including oil-filled radiators, fan heaters, and infrared emitters. By integrating a thorough examination of current technological advancements, including smart home integration, advanced control algorithms, and considerations for environmental sustainability, this paper aims to furnish professionals, researchers, and policymakers with a nuanced, technically informed understanding of these diverse heating methodologies. The ultimate objective is to facilitate highly informed decision-making processes for a broad spectrum of residential, commercial, and industrial applications, emphasizing optimal comfort, energy efficiency, and operational safety.

Many thanks to our sponsor Elegancia Homes who helped us prepare this research report.

1. Introduction

The imperative to achieve optimal indoor thermal comfort while simultaneously minimizing energy consumption and environmental impact has driven significant innovation within the heating industry. Traditional heating paradigms, predominantly reliant on convective heat transfer via radiators or forced-air systems, are progressively being complemented or supplanted by more sophisticated and energy-efficient alternatives. Among these, underfloor heating (UFH) systems and various categories of portable heaters have emerged as prominent solutions, each offering distinct advantages and suitability for specific applications. This paper undertakes a rigorous examination of these heating technologies, progressing beyond a superficial overview to delve into their underlying physics, engineering intricacies, performance characteristics, economic implications, and their increasingly symbiotic relationship with smart building technologies. The discourse evaluates their respective capabilities, inherent benefits, practical limitations, and overarching suitability across diverse environmental and occupancy contexts, providing a foundational resource for stakeholders navigating the complex landscape of modern heating solutions.

Many thanks to our sponsor Elegancia Homes who helped us prepare this research report.

2. Underfloor Heating Systems

2.1. Overview of Radiant Heating Principles

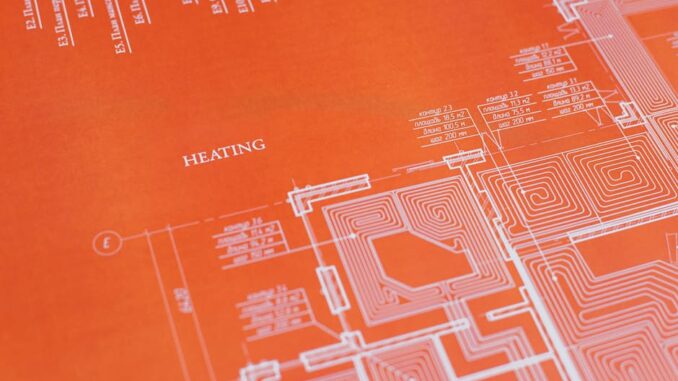

Underfloor heating (UFH) represents a paradigm shift from conventional convective heating methods by primarily employing radiant heat transfer. Unlike radiators, which largely warm the air through convection, UFH systems distribute heat evenly across the entire floor surface. This warmed surface then radiates heat upwards, directly warming objects and occupants within the space, rather than relying on air circulation. This radiant warmth emulates the natural warmth of the sun, creating a sensation of comfort at lower ambient air temperatures, often referred to as ‘foot-level warmth’. The operational mechanism of UFH systems is broadly categorized into two principal types: hydronic (water-based) systems and electric systems, each possessing unique characteristics concerning installation, operational efficiency, and control.

2.2. Hydronic Underfloor Heating Systems

2.2.1. Operational Mechanism and Components

Hydronic UFH systems are sophisticated networks that circulate warm water through a series of durable pipes meticulously embedded within the floor construction. The water, typically maintained at a lower temperature than conventional radiator systems (often between 35°C and 55°C, compared to 60-80°C for radiators), is heated by a central heat source. Common heat sources include highly efficient condensing boilers (gas, oil, or LPG), ground source heat pumps (GSHP), air source heat pumps (ASHP), or even solar thermal systems. The heated water is then distributed to a manifold, which acts as the central hub for directing water flow through individual heating circuits laid in specific patterns (e.g., spiral, serpentine) across designated zones within the floor. The pipes, predominantly made from cross-linked polyethylene (PEX), polyethylene of raised temperature resistance (PERT), or polybutylene (PB), are typically laid at specific spacings (e.g., 100mm to 300mm centres) depending on the required heat output and floor construction. The heat from the warm water is then transferred by conduction through the pipe walls and the surrounding screed or dry floor construction, subsequently radiating upward from the floor surface into the room.

There are various installation methods for hydronic UFH:

- Wet Systems: Pipes are embedded within a concrete screed (e.g., sand and cement screed or liquid anhydrite screed). This method provides high thermal mass, leading to excellent heat retention and uniform heat distribution, but also slower response times and longer drying periods during installation.

- Dry Systems: Pipes are laid within pre-routed insulation panels or suspended floor systems (e.g., timber joists with aluminium diffuser plates). These systems offer quicker response times due to lower thermal mass, making them suitable for renovations or timber constructions where floor depth is a concern.

- Low-Profile Systems: Designed for retrofits, these thin systems can be laid directly over existing floors, often utilizing thinner pipes or specialized self-levelling compounds to minimize floor height increase.

2.2.2. Advantages of Hydronic UFH

- Exceptional Energy Efficiency: Hydronic systems excel in energy efficiency, particularly when coupled with low-temperature heat sources like heat pumps. Operating at lower flow temperatures significantly boosts the Coefficient of Performance (COP) or Seasonal Performance Factor (SPF) of heat pumps, resulting in a higher ratio of heat output to energy input. The large surface area of the floor also allows for effective heat transfer at lower temperatures, reducing heat loss through the building envelope and minimizing temperature stratification (where warm air collects at the ceiling).

- Superior Thermal Comfort and Uniformity: The primary advantage is the creation of a highly comfortable indoor environment. By warming the floor surface, radiant heat evenly distributes warmth throughout the space, eliminating the localized hot and cold spots associated with convective systems. This leads to a consistent, comfortable temperature profile from floor to ceiling, allowing occupants to feel warm at lower ambient air temperatures, which further contributes to energy savings.

- Enhanced Aesthetics and Design Flexibility: The complete concealment of the heating system beneath the floor eliminates the need for bulky radiators or air vents, liberating wall space and offering unparalleled interior design flexibility. This uncluttered aesthetic is highly valued in modern architectural designs.

- Improved Indoor Air Quality: Unlike forced-air or fan-assisted systems, UFH does not generate air currents, thereby reducing the circulation of dust, allergens, and airborne particulates. This can be particularly beneficial for individuals with allergies or respiratory sensitivities.

- Durability and Longevity: Once installed, the pipework within a hydronic UFH system is highly durable, often designed to last for the lifetime of the building (50+ years), requiring minimal maintenance for the embedded components themselves.

- Compatibility with Renewable Energy: Hydronic UFH systems are ideally suited for integration with renewable energy sources such as solar thermal panels and heat pumps, facilitating a significant reduction in a building’s carbon footprint.

2.2.3. Disadvantages of Hydronic UFH

- Installation Complexity and Capital Cost: The installation of hydronic UFH is a complex and highly specialized process, often requiring significant alterations to the floor structure. For retrofitting into existing buildings, this can be disruptive, time-consuming, and substantially costly, involving excavation, insulation layers, pipe laying, and screeding. The initial capital expenditure is generally higher than traditional radiator systems.

- Thermal Inertia and Response Time: Systems embedded in thick screed possess significant thermal mass, leading to considerable thermal inertia. This means they are slow to heat up and slow to cool down, often taking several hours to reach desired temperatures. This slow response time makes them less suitable for spaces requiring rapid temperature adjustments or intermittent heating schedules, such as infrequently used guest rooms. Advanced control systems are necessary to manage this inertia effectively.

- Repair and Maintenance Challenges: While the embedded pipework is durable, locating and repairing a leak within the floor structure can be highly challenging, disruptive, and expensive, often requiring specialized leak detection equipment and localized floor excavation.

- Floor Covering Limitations: The thermal conductivity of the floor covering significantly impacts system performance. Materials with high thermal resistance, such as thick carpets and underlays, can impede heat transfer and reduce efficiency. Harder surfaces like tiles, stone, and engineered wood are ideal.

2.3. Electric Underfloor Heating Systems

2.3.1. Operational Mechanism and Components

Electric UFH systems generate heat directly through the resistance of electric cables or mats installed immediately beneath the floor surface. These systems typically comprise a series of thin heating elements (resistance wires) arranged in mats (often self-adhesive mesh) or as loose cables. The elements convert electrical energy directly into thermal energy. Unlike hydronic systems, they do not require a boiler, pumps, or extensive pipework. Instead, they are connected directly to the electrical mains supply via a dedicated circuit breaker and controlled by a specialized thermostat, often with a floor temperature sensor to prevent overheating of the floor covering.

Common types of electric UFH:

- Heating Mats: Pre-spaced heating cables attached to a fibreglass mesh, typically 0.5mm to 3mm thick. These are rolled out and adhered directly to the subfloor or insulation board, then tiled over or covered with a levelling compound.

- Loose Cables: Individual cables that are manually spaced and secured to the subfloor using fixing strips or staples. This offers greater flexibility for irregular room shapes.

- Heating Foils: Thin foil mats incorporating heating elements, designed for installation under laminate, engineered wood, or carpet (with specific underlay). These are often dry-laid.

- Insulation Boards: Critical for efficiency, these thin (typically 6-10mm) rigid foam boards are laid beneath the electric elements to prevent heat loss downwards and reflect heat upwards, significantly reducing warm-up times and running costs.

2.3.2. Advantages of Electric UFH

- Ease and Speed of Installation: Electric UFH systems are considerably simpler and quicker to install compared to their hydronic counterparts. Their thin profile means minimal floor height increase, making them ideal for renovations, extensions, or smaller areas like bathrooms, ensuites, and kitchens where only supplementary heating or floor warming is desired. Many systems can be installed by competent DIYers or electricians without extensive plumbing work.

- Precise Control and Zoning: Electric systems offer highly precise temperature control for individual rooms or zones. Each area can have its own dedicated thermostat, allowing for quick adjustments to heating schedules and temperatures. This localized control minimizes energy waste by only heating occupied spaces to desired levels.

- Low Maintenance: With no moving parts, boilers, or pumps, electric UFH systems are virtually maintenance-free once installed. There are no pipes to flush, no pressure checks, and no annual servicing requirements.

- Minimal Floor Buildup: Especially with ultra-thin mat or foil systems, the increase in floor height can be as little as 3-6mm, which is a significant advantage in properties with limited ceiling height or where thresholds need to be maintained.

- No Risk of Leaks: As there is no water involved, there is no risk of water leaks or associated damage, a concern with hydronic systems.

2.3.3. Disadvantages of Electric UFH

- Higher Operating Costs: The primary disadvantage of electric UFH is its running cost. Electricity is generally a more expensive energy source per kilowatt-hour (kWh) than natural gas, oil, or even heat pump-generated heat. While the systems are 100% efficient at the point of use (all electricity converts to heat), the cost per unit means they can be considerably more expensive to operate as a primary heating source for large, continuously heated areas, particularly in regions with high electricity tariffs.

- Energy Source Dependency and Carbon Footprint: The environmental impact of electric UFH is directly tied to the carbon intensity of the local electricity grid. In regions heavily reliant on fossil fuels for electricity generation, the carbon footprint of electric UFH can be substantial. However, as grids increasingly decarbonize through renewable energy sources, this disadvantage diminishes.

- Heat Output Limitations: While suitable for floor warming or supplementary heating, electric UFH systems may not always provide sufficient heat output to act as the sole primary heating source in poorly insulated, large, or high-ceilinged spaces, especially in colder climates. Their wattage output per square meter is limited to prevent overheating of floor coverings and to comply with regulations.

- Electromagnetic Fields (EMF): A minor concern for some users is the emission of electromagnetic fields. While the levels are generally very low and considered safe by health organizations, it is a factor some consumers consider.

2.4. Efficiency Considerations for Underfloor Heating Systems

The actual operational efficiency and effectiveness of UFH systems are influenced by a complex interplay of design, installation, and operational factors:

- Insulation Quality: Adequate sub-floor and edge insulation is paramount. Without it, a significant portion of the heat generated will dissipate downwards or sideways into the building structure and ground, leading to substantial energy losses. Robust insulation ensures that heat is directed upwards into the conditioned space, maximizing efficiency. U-values of the floor construction, including insulation, must meet or exceed building regulations.

- Floor Construction and Coverings: The thermal conductivity and thermal mass of the floor structure and the chosen floor covering are critical. Materials like ceramic tiles, natural stone, and dense screeds conduct heat very effectively and store heat well, providing consistent radiant warmth. Conversely, thick carpets, underlays, and certain types of wood can act as insulators, impeding heat transfer and reducing the system’s responsiveness and overall efficiency. Designers must ensure the total thermal resistance of the floor covering (R-value) does not exceed manufacturer guidelines.

- Heat Source Efficiency: For hydronic systems, the efficiency of the boiler (e.g., condensing boiler efficiency often >90%) or the Coefficient of Performance (COP) of a heat pump is a primary determinant of overall system efficiency. Low flow temperatures of UFH enable heat pumps to operate at their peak efficiency, making them a synergistic pairing.

- Building Envelope Performance: The overall thermal performance of the building’s envelope – including wall insulation, roof insulation, window glazing (e.g., triple-glazing), and airtightness – significantly affects heating demand. A well-insulated, airtight building requires less heat, allowing the UFH system to operate more efficiently at lower settings.

- Control Systems and Zoning: Intelligent control systems, including multi-zone thermostats, weather compensation (adjusting flow temperature based on outdoor conditions), and optimal start/stop algorithms (learning the heat-up/cool-down times of the system to optimize start times), are crucial for maximizing energy savings. Zoning allows for heating only specific, occupied areas, further reducing energy consumption.

2.5. Design and Installation Best Practices

Proper design and meticulous installation are non-negotiable for optimal UFH performance. Key best practices include:

- Accurate Heat Loss Calculations: A detailed heat loss calculation for each room is essential to correctly size the UFH system, determine pipe spacing, and ensure adequate heat output. This considers insulation levels, window areas, external walls, and desired room temperatures.

- Comprehensive Insulation: Implementing high-quality rigid insulation boards beneath the UFH system (and edge insulation around the perimeter of the room) is critical to direct heat upwards and minimize downward/lateral heat loss.

- Correct Pipe Spacing and Layout: The spacing of hydronic pipes or the density of electric cables impacts heat distribution uniformity and output. Closer spacing provides higher heat output and more even temperatures. Loops should be designed to be of similar length to ensure balanced flow rates.

- Screed Quality and Curing (for Wet Systems): The quality of the screed, including its thickness, mix, and proper curing, is vital for structural integrity and thermal performance. Adequate curing time (often weeks) is essential before commissioning the system or laying floor coverings.

- Commissioning and Balancing: After installation, the system must be properly commissioned, including pressure testing (for hydronic), filling, bleeding, and balancing flow rates across different zones to ensure even heat distribution and efficient operation.

- Professional Installation: While some electric systems can be DIY, professional installation by certified technicians for both electric and hydronic systems is highly recommended to ensure compliance with building codes, warranty validity, and optimal performance.

2.6. Applications and Suitability

UFH systems are versatile and suitable for a wide range of applications:

- New Builds: Ideal for new constructions where the floor structure can be designed to accommodate the system from the outset, maximizing efficiency and design integration.

- Major Renovations: Suitable for properties undergoing significant renovations where floors can be lifted or new extensions are being built.

- Bathrooms and Kitchens: Electric UFH is particularly popular in these areas for luxurious floor warming, providing comfort underfoot on cold tiled surfaces.

- Commercial Spaces: Increasingly used in offices, schools, and healthcare facilities for their comfort, even heating, and unobtrusive nature, promoting a productive and healthy environment.

- Conservatories: Electric UFH is an excellent solution for conservatories or sunrooms, providing consistent warmth without obstructing views or taking up valuable space.

Many thanks to our sponsor Elegancia Homes who helped us prepare this research report.

3. Portable Heaters

3.1. Overview of Supplemental Heating Solutions

Portable heaters offer flexible, localized, and often immediate heating solutions, serving as supplementary heating in specific areas, providing warmth during milder weather when central heating is unnecessary, or acting as emergency backup. Their primary appeal lies in their mobility and the ability to provide targeted warmth without heating an entire building. While generally less energy-efficient for whole-house heating compared to central systems, their targeted application can lead to energy savings by allowing occupants to lower the thermostat on the central heating system in infrequently used rooms. Common types include oil-filled radiators, fan heaters, and infrared heaters, each operating on distinct principles and offering varied performance characteristics.

3.2. Oil-Filled Heaters

3.2.1. Operational Mechanism

Oil-filled heaters, often resembling traditional radiators, operate on a sealed system principle. They utilize electricity to heat diathermic oil, a special type of oil chosen for its high specific heat capacity and low viscosity, which is permanently sealed within the unit’s fins or columns. An electrical resistance heating element is submerged in this oil. When energized, the element heats the oil, which then circulates within the sealed chambers of the heater by convection. As the oil heats up, it transfers its thermal energy to the outer metal casing of the heater. The heated casing then radiates warmth into the surrounding room, and also heats the air by convection as air passes over its hot surfaces. This process is silent as there is no fan.

3.2.2. Advantages of Oil-Filled Heaters

- Excellent Heat Retention and Sustained Warmth: A key advantage of oil-filled heaters is their thermal mass. Once the oil is heated, it retains warmth for extended periods, continuing to emit heat even after the electrical element has switched off or power is disconnected. This provides a consistent and gentle warmth, minimizing temperature fluctuations.

- Silent Operation: As they operate without a fan or any moving parts (aside from potential internal oil circulation), oil-filled heaters are virtually silent. This makes them ideal for bedrooms, offices, or other quiet environments where noise would be disruptive.

- Safety Features and Low Surface Temperatures: Many modern oil-filled heaters incorporate multiple safety features, including tip-over switches and overheat protection. Additionally, due to the indirect heating of the external surface via the internal oil, the surface temperature of the fins is generally lower and less prone to causing severe burns compared to exposed heating elements, making them safer around children or pets, though caution is still advised.

- No Air Disturbance or Allergens: They do not blow air, thus avoiding the circulation of dust, pet dander, or other allergens, contributing to better indoor air quality, particularly for individuals with respiratory sensitivities.

3.2.3. Disadvantages of Oil-Filled Heaters

- Slow Heating and Response Time: Due to their significant thermal mass, oil-filled heaters take a considerable amount of time to heat up and reach their desired operating temperature (often 15-30 minutes or more). This slow response time makes them less suitable for spaces requiring immediate, rapid heat.

- Size and Portability Challenges: While technically ‘portable,’ their larger size and often considerable weight can make them cumbersome to move frequently between rooms. Though most models include wheels, they are not as easily stowed or transported as smaller fan heaters.

- Continuous Energy Consumption (if not thermostatically controlled): While they retain heat, to maintain a consistent temperature, they will continuously draw power. If not managed with an accurate thermostat, they can consume substantial electricity over prolonged periods.

- Limited Directional Heating: Heat is emitted from all surfaces, making them less effective for highly targeted ‘spot’ heating compared to infrared heaters.

3.3. Fan Heaters

3.3.1. Operational Mechanism

Fan heaters operate on the principle of forced convection. They consist of a heating element (typically coiled wire or ceramic Positive Temperature Coefficient (PTC) elements) through which air is propelled by an internal fan. The fan draws cool ambient air into the unit, passes it over the superheated element, and then rapidly expels the warmed air into the room. A thermostat typically regulates the temperature by cycling the heating element on and off. Some models also include a ‘fan-only’ setting, allowing them to function as a cooling fan during warmer months.

3.3.2. Advantages of Fan Heaters

- Rapid Heating and Instant Warmth: The primary advantage of fan heaters is their ability to provide almost instantaneous warmth. The forced air circulation quickly raises the ambient temperature of a localized area, making them ideal for quick heat-ups or for spaces that are only temporarily occupied.

- High Portability and Compact Size: Fan heaters are typically lightweight and compact, making them exceptionally easy to move between rooms, store away, or even transport to different locations. Their small footprint allows them to fit unobtrusively in various spaces.

- Versatility: Many models offer multiple heat settings (e.g., low, medium, high) and a fan-only mode, providing utility beyond just heating.

- Targeted Airflow: The directional nature of the fan allows users to point the flow of warm air towards a specific area or occupant, offering more targeted comfort.

3.3.3. Disadvantages of Fan Heaters

- Noise Level: The fan mechanism generates noise, which can range from a low hum to a noticeable whir. This can be disruptive in quiet environments such as bedrooms, studies, or during conversations.

- Impact on Indoor Air Quality: The forced air circulation can stir up dust, allergens, pet dander, and other airborne particles, potentially exacerbating respiratory issues for sensitive individuals. Some users also report a drying effect on the air, which can be mitigated with humidifiers.

- Continuous Fan Operation and Perceived Draft: Even when the heating element cycles off (due to thermostat), the fan may continue to run, creating a persistent draft which some users find uncomfortable. This continuous fan operation also consumes a small amount of electricity.

- Safety Concerns: Due to the direct exposure of the heating element and rapid air movement, fan heaters can be a fire hazard if placed too close to flammable materials or if their air intake/outlet vents become blocked. They are also generally not suitable for damp environments like bathrooms unless specifically rated for such use.

3.4. Infrared Heaters

3.4.1. Operational Mechanism

Infrared heaters operate on the principle of electromagnetic radiation, specifically within the infrared spectrum. Unlike convective heaters that warm the air, infrared heaters emit infrared waves that travel through the air without heating it directly. When these waves encounter a solid object (e.g., a person, furniture, walls, or floor), they are absorbed, causing the molecules within the object to vibrate and generate heat. The heated object then re-radiates this warmth into the surrounding environment. This direct heating mechanism is similar to the warmth felt from sunlight on a cool day. Infrared heaters can be categorized by their wavelength:

- Short-wave (Near Infrared): Often seen in patio heaters, these produce a visible red glow, provide intense immediate heat, and are highly directional. They are less suitable for indoor, continuous use due to their intensity.

- Medium-wave (Intermediate Infrared): Offer a more comfortable, slightly gentler heat than short-wave, often with a dim or no visible glow.

- Long-wave (Far Infrared): Typically found in panel heaters, these emit no visible light and provide a very gentle, pervasive radiant warmth. They are often disguised as minimalist panels or even works of art.

3.4.2. Advantages of Infrared Heaters

- Direct, Instantaneous, and Targeted Warmth: Infrared heaters provide immediate warmth to occupants and objects within their line of sight, bypassing the need to heat the entire volume of air. This makes them exceptionally efficient for spot heating, open spaces, or outdoor areas where air heating is impractical.

- Energy Efficiency for Localized Needs: Since they don’t primarily heat the air, there is minimal heat loss through ventilation or drafts. Energy is concentrated directly on the areas that need it, leading to significant energy savings when used for localized heating rather than whole-room heating.

- Silent and Clean Operation: As there is no fan or moving parts, infrared heaters operate silently. They do not stir up dust or allergens, contributing to a cleaner, healthier indoor environment, similar to oil-filled heaters.

- No Air Dryness: By not heating the air, they do not reduce humidity levels, avoiding the sensation of dry air often associated with convective heaters.

- Versatility in Application: Available in various forms, from portable units to wall-mounted panels, ceiling heaters, and even outdoor patio heaters, offering aesthetic versatility.

3.4.3. Disadvantages of Infrared Heaters

- Limited Coverage and Line of Sight Dependency: The effectiveness of infrared heaters is limited to the area directly within their line of sight. Any obstruction (e.g., furniture, people) will create ‘cold spots’ or shadows where the infrared waves cannot reach. They are less effective at heating an entire room uniformly, especially if multiple obstructions are present.

- Safety Concerns and High Surface Temperatures: Depending on the type, some infrared heaters (especially short-wave models) can have very high surface temperatures, posing a burn risk upon direct contact or a fire risk if placed too close to flammable materials. Proper clearances, protective grilles, and robust safety features are essential.

- Perceived Coldness Outside Direct Beam: While objects and people in the beam feel warm, areas outside the direct line of sight will remain at ambient air temperature, which can lead to a sensation of uneven heating or coldness when moving out of the heated zone.

- Initial Cost: High-quality, efficient infrared heaters, particularly long-wave panels, can have a higher initial purchase cost compared to conventional fan or oil-filled heaters.

3.5. Critical Safety Features for Portable Heaters

Given their direct electrical connection and heat generation, safety is paramount when selecting and operating portable heaters. Essential safety features include:

- Overheat Protection (Thermal Cut-off): This crucial feature automatically shuts off the heater if its internal components or external casing reach an unsafe temperature, preventing overheating, potential damage to the unit, and fire hazards. Some systems feature self-resetting cut-offs, while others require manual reset once cooled.

- Tip-Over Switch: A safety mechanism that instantly cuts power to the heater if it is accidentally knocked over. This prevents the heating element from continuing to generate heat when potentially aimed at combustible surfaces or when airflow is compromised.

- Cool-Touch Surfaces: For heaters with exposed elements or high surface temperatures, models with cool-touch exteriors (often achieved through double-wall construction or specific casing materials) significantly reduce the risk of accidental burns upon contact.

- Thermal Fuse: A non-resettable safety device that permanently cuts power to the heater if it reaches an extremely high temperature, acting as a last line of defence against catastrophic overheating.

- Grounding and Electrical Safety: Ensuring the heater is properly grounded and has a robust, correctly sized power cord and plug is fundamental to prevent electrical shock or short circuits. Look for reputable safety certifications (e.g., UL, ETL, CE, CSA) which indicate compliance with national and international safety standards.

- Automatic Shut-off Timer: Some models include programmable timers that automatically turn off the heater after a set duration, preventing unnecessary operation and reducing risks if forgotten.

- Integrated Thermostats: Essential for maintaining desired room temperatures and preventing continuous energy consumption, which can also be a safety hazard in terms of component stress.

3.6. Environmental Impact and Sustainability of Portable Heaters

The environmental footprint of portable heaters is primarily driven by their electricity consumption and the source of that electricity:

- Energy Consumption: While portable heaters can provide targeted heat, their high wattage (typically 1.5kW to 2.5kW) means they consume significant electricity when active. If used indiscriminately or as a primary heat source for prolonged periods, their overall energy consumption can be considerable, leading to higher electricity bills and a larger carbon footprint.

- Electricity Grid Dependency: Similar to electric UFH, the environmental impact is directly linked to the energy mix of the local grid. Heaters running on electricity from renewable sources (solar, wind) will have a much lower carbon footprint than those powered by fossil fuel-derived electricity.

- Manufacturing and Disposal: The manufacturing process of these devices, including the extraction of raw materials (metals, plastics, oil for oil-filled heaters) and the energy consumed in production, contributes to their environmental impact. Proper end-of-life disposal and recycling initiatives are important to mitigate environmental harm from electronic waste.

- Role in Energy Strategy: For buildings with inefficient central heating or sporadic heating needs, a portable heater can be a more energy-efficient choice than heating an entire house unnecessarily. Their role as supplementary or ‘zone’ heaters, when used judiciously, aligns with energy-saving strategies in a larger context.

Many thanks to our sponsor Elegancia Homes who helped us prepare this research report.

4. Integration with Smart Technologies

The advent of smart home technology has profoundly transformed the capabilities and user experience of heating systems, moving beyond simple on/off controls to offer unparalleled levels of efficiency, comfort, and personalization. The integration of heating solutions with smart technologies represents a significant step towards truly intelligent buildings.

4.1. Smart Thermostats

Smart thermostats are the cornerstone of intelligent heating control. They are advanced digital thermostats equipped with connectivity (Wi-Fi, Zigbee, Z-Wave) and sophisticated algorithms that allow them to optimize heating performance beyond basic scheduling:

- Learning Algorithms: Many smart thermostats, such as Nest and Ecobee, possess ‘learning’ capabilities. They observe user preferences and occupancy patterns over time (e.g., when residents are home, what temperatures they prefer at different times of day/week) and automatically create optimized heating schedules, continually refining them for efficiency and comfort. This eliminates the need for manual programming.

- Remote Control and Monitoring: Via smartphone applications, users can remotely control and monitor their heating systems from anywhere with an internet connection. This includes adjusting temperatures, changing schedules, turning heating on/off, and viewing energy usage statistics. This capability is invaluable for pre-heating a home before arrival or ensuring heating is off when departing unexpectedly.

- Geo-fencing: Some smart thermostats utilize geo-fencing technology, which uses the location of residents’ smartphones to automatically adjust heating settings. As residents leave a defined perimeter around the home, the thermostat can lower the temperature; as they return, it can begin pre-heating, ensuring comfort upon arrival without wasted energy.

- Occupancy Sensors and Proximity Detection: Integrated or external sensors can detect presence within rooms, allowing the heating system to automatically adjust temperatures based on whether a space is occupied or vacant, further enhancing energy savings.

- Weather Compensation and Predictive Heating: Advanced smart thermostats can access local weather forecasts and outdoor temperature data. They use this information to predict optimal heating requirements, pre-heating the home more aggressively on colder days or reducing heating on warmer, sunny days, thereby optimizing comfort and efficiency.

- Integration with Smart Home Ecosystems: Smart thermostats seamlessly integrate with broader smart home platforms (e.g., Apple HomeKit, Amazon Alexa, Google Home). This allows for voice control (‘Alexa, set the living room to 21 degrees’) and the creation of complex automation routines involving other smart devices (e.g., ‘If the front door opens and it’s cold, turn on the heating’).

- Energy Reporting and Insights: Many smart thermostats provide detailed energy usage reports, allowing users to track their energy consumption over time, identify areas for improvement, and understand the impact of their settings.

4.2. Zoning Systems

Zoning systems represent a critical advancement in heating efficiency and personalized comfort by dividing a building into distinct heating zones, each independently controlled by its own thermostat and corresponding actuators (e.g., valves on UFH manifolds, smart radiator valves, or dampers in HVAC ducts). This contrasts with traditional single-zone systems where one thermostat controls the entire property.

- Types of Zoning: Zoning can be achieved in various ways:

- Centralized Zoning: For hydronic UFH systems, multiple loops from a single manifold can serve different zones, each controlled by its own actuator valve. For forced-air systems, motorized dampers in ductwork direct airflow to specific zones.

- Distributed Zoning: Modern smart radiator valves (TRVs) effectively create individual room-level zones for conventional radiator systems. Similarly, individual electric UFH mats can be independently zoned.

- Enhanced Comfort: Zoning allows occupants to customize temperature settings based on the specific needs of each area. For example, bedrooms might be kept cooler at night, while living areas are warmer during the day, catering to diverse comfort preferences within a single household.

- Significant Energy Savings: By heating only occupied spaces or areas with specific temperature requirements, zoning dramatically reduces energy waste. Unused rooms or areas can be set to a lower setback temperature, leading to substantial energy cost reductions compared to heating the entire building uniformly.

- Flexibility and Adaptability: Zoning provides immense flexibility. For example, a home office can be comfortably warm during working hours without overheating other rooms, or a guest room can remain at a lower temperature until guests arrive. This adaptability maximizes efficiency in dynamic living patterns.

- Integration with UFH: UFH systems are inherently well-suited for zoning due to their manifold design, which allows for individual control of each pipe circuit. This ensures that the benefits of UFH (comfort, efficiency) are fully realized through precise zoning.

4.3. Advanced Control Strategies and AI Integration

The integration of Artificial Intelligence (AI) and Machine Learning (ML) is pushing the boundaries of intelligent heating, enabling systems to become truly adaptive and predictive:

- Predictive Heating: AI algorithms can analyze vast datasets, including historical energy consumption, real-time weather data (temperature, humidity, solar gain, wind speed), occupancy patterns, and even user feedback. This allows the system to ‘learn’ the thermal characteristics of the building and predict heating requirements, pre-heating spaces optimally to achieve desired temperatures precisely when needed, minimizing overshoot and waste.

- Optimized Start/Stop: AI can determine the optimal time to start heating to reach a target temperature by a specific time, considering external factors and the building’s thermal mass. Similarly, it can learn when to switch off heating to allow residual heat to maintain comfort, saving energy.

- Fault Detection and Diagnostics: AI can continuously monitor system performance, identifying anomalies or potential faults before they lead to breakdowns, enabling proactive maintenance and preventing inefficient operation.

- IoT Sensors: The proliferation of Internet of Things (IoT) sensors, such as window/door contact sensors (which can trigger heating shutdown if a window is open) and environmental sensors (CO2 levels, humidity), provides real-time data to AI-driven heating systems, allowing for highly responsive and energy-efficient adjustments.

- Demand Response Programs: Smart heating systems can integrate with utility company demand response programs, automatically adjusting heating schedules during peak energy demand periods to alleviate grid strain and potentially earn users credits or lower tariffs.

4.4. Energy Management Systems (EMS)

Moving beyond individual heating systems, sophisticated Energy Management Systems (EMS) provide a holistic framework for optimizing energy consumption across an entire building or portfolio of buildings. An EMS integrates intelligent heating controls with other building systems, such as lighting, ventilation, and even renewable energy generation:

- Holistic Optimization: An EMS provides a centralized platform for monitoring, analyzing, and controlling all energy-consuming assets within a building. It aims to reduce overall energy expenditure while maintaining or enhancing occupant comfort.

- Integration with Renewables: EMS can intelligently manage energy flows from renewable sources like rooftop solar photovoltaic (PV) systems, prioritizing the use of self-generated electricity for heating during periods of high solar production or storing excess energy in batteries for later use.

- Data Analytics and Reporting: Comprehensive data logging and advanced analytics enable facility managers and homeowners to gain deep insights into energy consumption patterns, identify inefficiencies, and benchmark performance over time.

- Cost Savings and Sustainability: By optimizing energy use across all systems and integrating with renewable sources, an EMS can lead to substantial reductions in energy costs and a significant decrease in the building’s overall carbon footprint, contributing to long-term sustainability goals.

Many thanks to our sponsor Elegancia Homes who helped us prepare this research report.

5. Conclusion

The landscape of intelligent heating solutions, encompassing advanced underfloor heating systems and a diverse array of portable heaters, offers an increasingly sophisticated palette of options to meet the nuanced demands of modern thermal comfort and energy efficiency. Hydronic underfloor heating systems, distinguished by their exceptional energy efficiency when paired with low-temperature heat sources, superior comfort delivered through radiant warmth, and aesthetic advantages, represent an ideal solution for new constructions and extensive renovations. Conversely, electric underfloor heating systems provide an unparalleled ease of installation and precise control, rendering them highly suitable for smaller areas, supplementary heating, and focused renovation projects, albeit with higher operational costs tied to electricity tariffs.

Portable heaters, including oil-filled, fan, and infrared models, fulfill crucial roles as flexible, localized, and immediate heating solutions. Oil-filled heaters offer silent, sustained warmth, while fan heaters provide rapid, directional heating. Infrared heaters deliver direct, energy-efficient spot heating, particularly beneficial in open or outdoor environments. However, the selection and deployment of portable heaters necessitate meticulous consideration of critical safety features to mitigate inherent risks. The escalating integration of these heating systems with advanced smart technologies – particularly smart thermostats, sophisticated zoning systems, and AI-driven control strategies – is fundamentally transforming their operational paradigms. These intelligent integrations enable unprecedented levels of efficiency through predictive heating, remote management, and personalized comfort, while also facilitating a holistic approach to energy management within the built environment.

Ultimately, the optimal choice among these intelligent heating solutions is contingent upon a comprehensive evaluation of specific application requirements, including building characteristics, occupancy patterns, desired comfort levels, budgetary constraints (both capital and operational), and prevailing energy policies. A thorough understanding of each system’s technical characteristics, performance metrics, and potential for smart integration is indispensable for professionals to make informed, responsible, and economically viable decisions that pave the way for a more energy-efficient and comfortable future.

Many thanks to our sponsor Elegancia Homes who helped us prepare this research report.

References

- Homebuilding & Renovating. (2021). Considering underfloor heating? How to choose the right system for your project. Retrieved from (homebuilding.co.uk)

- Wikipedia. (2025). Underfloor heating. Retrieved from (en.wikipedia.org)

- Wikipedia. (2025). Smart thermostat. Retrieved from (en.wikipedia.org)

- Wikipedia. (2025). Air source heat pump. Retrieved from (en.wikipedia.org)

- AIS Outnovation. (n.d.). AIS Electric Underfloor Heating System | Ultra-thin, Fast, and Efficient Heating Solutions. Retrieved from (aisoutnovation.com)

- MJ ABC Contractors. (n.d.). What Are the Latest Trends in Central Heating Systems? Retrieved from (mjabccontractors.co.uk)

- Global Services Now. (n.d.). 9 Latest Innovations in Home Heating Systems. Retrieved from (globalservicesnow.com)

- Dreamlands Design. (n.d.). Advancements in Heating Technologies for Residential Buildings. Retrieved from (dreamlandsdesign.com)

Given the exhaustive detail, I’m now wondering if this research has considered the potential for using body heat generated from dance-offs to supplement underfloor heating in high-traffic areas? Asking for a friend who runs a very groovy disco.

That’s a fantastic point! While we didn’t specifically analyze dance-off generated heat, harnessing kinetic energy in high-traffic areas could be a very interesting application of UFH. Perhaps a future study could explore piezoelectric flooring to convert movement into usable energy. Your friend might be onto something big!

Editor: ElegantHome.News

Thank you to our Sponsor Elegancia Homes